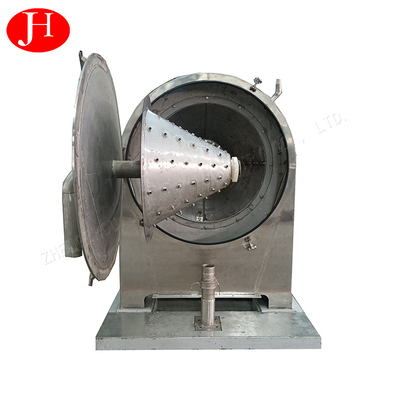

Centrifuge Sieve Equipment Cassava Starch Slurry Separator Making Machine

Product Details:

| Place of Origin: | Henan |

| Brand Name: | JingHua |

| Model Number: | Centrifuge Sieve |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 1640*2490*2222 mm |

| Delivery Time: | 10 work days |

| Payment Terms: | L/C, D/P, D/A, Western Union, T/T, MoneyGram |

| Supply Ability: | 10 |

|

Detail Information |

|||

| Product Name: | Centrifuge Sieve | Application: | Food Industry Machinery |

|---|---|---|---|

| Function: | Multifunction Flour Grinder | Final Products: | Super Fine Flour |

| Type: | Food Processing Machine | Processing Type: | Cleaning-milling-packing |

| Highlight: | High Efficiency Cassava Centrifugal Sieve,Cassava Starch Slurry Separator Making Machine,Industry Cassava Starch Slurry Separator Machine |

||

Product Description

Centrifugal Sieve is used to separate the fine fiber from the starch slurry, which is widely used in the processing of potato, cassava, sweet potato,

wheat, rice, sago and other grain starch extraction.

Main technical parameters

|

Model |

Basket diameter (mm) |

Main shaft speed (r/min) |

Working model |

Power (Kw) |

Dimension (mm) |

Weight (t) |

|

DLS85 |

850 |

1050 |

continuous |

18.5/22/30 |

1200x2111x1763 |

1.5 |

|

DLS100 |

1000 |

1050 |

continuous |

22/30/37 |

1440x2260x1983 |

1.8 |

|

DLS120 |

1200 |

960 |

continuous |

30/37/45 |

1640x2490x2222 |

2.2 |

Advantages of Centrifugal Sieve

1. Integrating the latest technology and years of experience.

2. The key components are imported from abroad, with long service life and low maintenance cost.

3. All parts in contact with materials are made of stainless steel, without material pollution.

4. The sieve basket is calibrated by domestic authoritative organization.

5. Titanium alloy plate laser perforated screen.

6. It is convenient for the automatic design of the centrifugal screen group, and can easily realize the automatic control of the CIP system and the

chain.

7. Advanced surface treatment technology ensures good appearance and oil resistance.

8. The nozzle has been strictly tested for pressure and flow.

9. Large processing capacity, low power consumption, stable operation, high starch extraction rate, and easy installation.

10. Widely used in starch processing plants to extract starch.

Pre-sale service

1. Accept customer consultation and customize products according to customer requirements.

2. Provide customers with product process, equipment parameters and processes, and train personnel according to customer requirements.

Sale service

1. The company sent technical personnel to the scene of the on-the -spot guidance equipment installation,debugging and training operators.

2. If there is any problem during the installation, please contact the responsible person in time. We will solve the problem in time to ensure the installation progress.

After-sale service

1. Provide telephone and video support. If the customer has any problems or abnormal devices in use, you can contact us by phone. We will help the customer solve the problems by phone or video.

2. If the phone or video doesn't work, the company will send technicians to the scene to fix the problem.

3. Products purchased in our company, we provide one-year warranty and lifelong maintenance service.

Q1: Can you provide detailed parameters and drawings of the equipment?

A: Yes, you can contact us by email, we will provide you with the detailed parameters and drawings of the equipment.

Q2:How long is the warranty period of the equipment?

A:After the successful installation and commissioning of the equipment, there is a one-year warranty period.

Q3:What kind of after-sales service do you provide?

A:Provide after-sales service for customers through telephone, video guidance, on-site maintenance, etc.

Q4: Are your products can be assured ?

A: Our machines are all passed ISO9001:2001 and have CE certificate by SGS, TUV.

Q5: If we show you our layout of factory, can you help us to design the whole process line?

A : Yes, our experienced engineers and technical employees can help you to arrange the layout and installation of whole process line based on your real situation;

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.

![]()

![]()