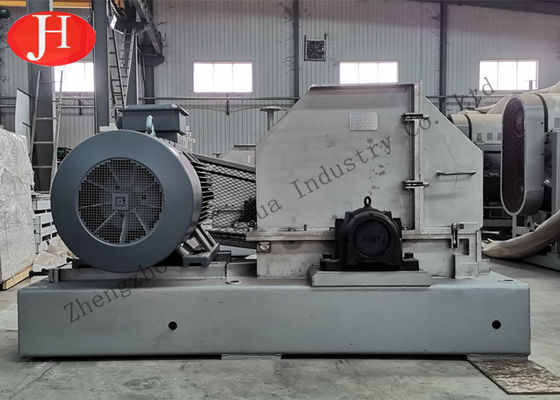

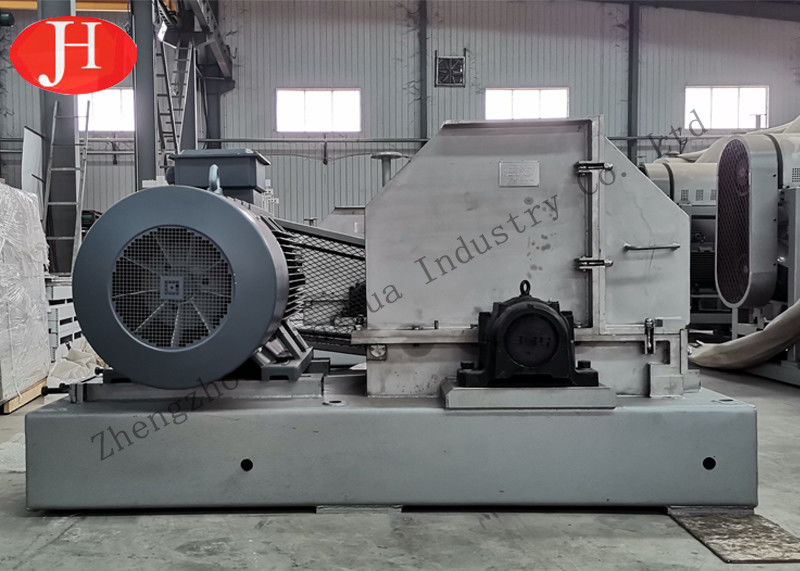

250Kw Stainless Steel Rasper Sweet Potato Starch Machine

Product Details:

| Place of Origin: | Zhengzhou City,China |

| Brand Name: | JINGHUA |

| Certification: | CE |

| Model Number: | DCM8435 DCM8450 DCM8465 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Customize the wooden case according to the size of the product,Each container can hold 4-6 pieces of products |

| Delivery Time: | 5-14 work days after receiving pre payment |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 10 sets/month |

|

Detail Information |

|||

| Product Name: | Stainless Steel Rasper | Useful Life: | 20 Years |

|---|---|---|---|

| Customized: | Customized | Energy: | Electric |

| Dimension: | 3000*1590*1500 Mm | Capacity: | 10-45 T/h |

| Application: | Sweet Potato Grinder Machine | Main Shaft Rotating Speed: | 2100 R/min |

| Highlight: | 2100r/Min Sweet Potato Starch Machine,250Kw Stainless Steel Rasper,Potato Starch Grinder Machine |

||

Product Description

Sweet Potato Starch Grinder Mill Making Machine 250 Kw Large Capacity Rasper

Description of sweet potato grinder machine

The rasper in high speed to crushing raw materials, destroy the fiber structure, starch particles free, for the company's high-tech products and patented technology products. Widely used in canna, cassava, potato and other materials such as secondary grinding.

Main technical parameters

| Model | DCM8435 | DCM8450 | DCM8465 | DCM1070 |

| Main shaft rotating speed(r/min) | 2100 | 2100 | 2100 | 1470 |

| Drum diameter (mm) | Φ840 | Φ840 | Φ840 | Φ1100 |

| Drum width (mm) | 350 | 500 | 650 | 700 |

| Power (Kw) | 110 | 160 | 200 | 250 |

| Capacity (t/h) | 20-23 | 30-33 | 35-40 | 40-45 |

| Dimension(mm) | 2170x1260x1220 | 2170x1385x1250 | 2170x1650x1380 | 3000x1590x1500 |

Key Technology & Innovation Potions

1. All parts in contact with raw material are made of food-grade stainless steel, which protects materials from outer pollution.

2. High rotating speed, high line speed, excellent rasping performance, uniform particle, and high starch ionization rate.

3. Rotor is calibrated with international advanced dynamic-balance instrument, meeting G1 standard.

4. Components(bearings for example) are imported from Europe with longer service life

5. Unique sieve-tension gear makes disassembly easy.

6. Saw Blade is manufactured with special steel by special process, with higher hardness and wear resistance.

7. Rasping bulk is cast of high-chromium iron, hardness reaching HRC60, having excellent wear resistance.

8. Unique drum groove and layering instrument design benefits saw blade changing.

Real application case

![]()

The working principle of rasper

The material enters into the body of the file mill shell through the upper entrance, and is broken by the impact, shear and grinding effect of the saw blade moving at high speed. The lower part of the rotor is equipped with a screen screen. The material smaller than the size of the screen hole is discharged through the screen plate, and the particles larger than the size of the screen hole are blocked and remain on the screen plate to continue to be hit and grinder by the saw blade.

Our Customer

![]()

Company Information

Jinghua company is a specialized engineering technology company specializing in various starch engineering design, equipment manufacturing, engineering installation and debugging, technical personnel training and other work. Has two modern large factory, engineering and technical personnel more than 30 people, can provide installation services overseas. Our company has undertaken national and provincial scientific research projects.,with more than 30 invention patents, various honor certificate more than 20.The chairman of the board is professor wang yanbo, who is mainly engaged in theoretical research on the transformation and utilization of grain resources, teaching, scientific research and engineering design of starch and its deep processing direction, and research and development of modern equipment. He has published 7 scientific works, 6 national standards and 30 academic papers.

![]()

![]()