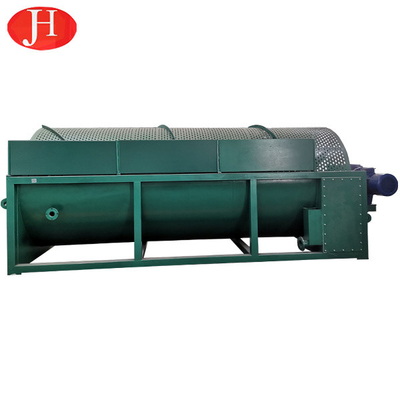

Automatic Sweet Potato Rotary Washer Starch Making Production Equipment

Product Details:

| Place of Origin: | Henan |

| Brand Name: | JingHua |

| Model Number: | Rotary Washer |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 7050*2300*2000 mm |

| Delivery Time: | 10 work days |

| Payment Terms: | L/C, D/P, D/A, Western Union, T/T, MoneyGram |

| Supply Ability: | 10 |

|

Detail Information |

|||

| Product Name: | Cassava Starch Processing Equipment | Application: | Sweet Potato |

|---|---|---|---|

| Final Products: | Super Fine Flour | Usage: | Powder Milling |

| Feature: | Easy Operation | Function: | Multifunction |

| Processing: | Cleaning-degerminating-milling-packing | Processing Type: | Cleaning-milling-packing |

| Highlight: | Sweet Potato Rotary Washer,Powder Milling Rotary Washer,Automatic Starch Rotary Washer |

||

Product Description

Automatic Sweet Potato Rotary Washer Starch Making Production Equipment

The drum washing machine is suitable for cleaning potatoes, cassava, sweet potatoes, etc. The drum washing machine is a washing machine in

the starch

The treatment line adopts the principle of countercurrent to effectively remove mud, sand and small stones.

|

Model |

Drum Diameter |

Drum Length |

Capacity |

Power |

Dimension(mm) |

Weight |

|

QXJ-15 |

1705 |

3000 |

12-15 t/h |

15kw |

3830*1880*1757 |

3000 kg |

|

QXJ-20 |

1905 |

4520 |

20-25 t/h |

18.5kw |

5400*2810*2810 |

5200 kg |

|

QXJ-30 |

1950 |

4920 |

30-35 t/h |

22kw |

5930*2810*2810 |

5730 kg |

2. The countercurrent washing method is adopted, the washing effect is good, and the sediment is removed.

3. Reasonable feeding structure. The crushing rate of raw materials is less than 1%, ensuring high starch extraction rate.

Jinghua Company is a company specializing in various starch engineering design, equipment manufacturing,

Engineering installation and commissioning, technical personnel training, etc. Has two modern large workshops, engineering technology

More than 30 people can provide overseas installation services. The chairman is Professor Wang Yanbo, who is mainly responsible for

Engaged in theoretical research, teaching, scientific research and engineering design of food resources transformation and utilization

Starch and its deep processing direction, research and development of modern equipment. Published 7 academic books and 6 national books

Standard and 30 academic papers.

![]()

pre-sale service

1. Introduce the detailed features and applications of the product to customers.

2. Choose economical and practical machines for customers.

3. Provide operating data of related machines.

4. Provide audition means for customers.

5. Flow chart and factory design layout.

In-sale service

1. Recommend the engineering conditions required for machine installation.

2. Communicate with customers about the progress of machine manufacturing in a timely manner.

3. Project planning and design services.

After-sales service

1. Equipment maintenance and operation training.

2. Install and commission the device until everything is in order.

3. One-year warranty, long-term maintenance services and spare parts are provided.

4. Provide technical support for customers to develop new products.

5. Engineers can service machinery overseas.

Q1: Is your company a factory or trading company?

A: Our company is a factory in Henan Province ,with export license and we have done export business over 20 years professionally.

Q2. What is your main business?

A: ZZJH is devoted to starch processing machine. The machine of starch processing line , such as : cassava starch line , cassava flour line , potato starch line , sweet potato line , wheat starch ,sago line and garri line

Q3: Where is your factory located? How can I visit there?

A: Our add: Zhengyun Road and Guanggu Road intersection , Guangwu Town , Zhengzhou City , Henan Province , China.

Warmly welcome to visit us!

Q4: Are your products can be assured ?

A: Our machines are all passed ISO9001:2001 and have CE certificate by SGS, TUV.

Q5: If we show you our layout of factory, can you help us to design the whole process line?

A : Yes, our experienced engineers and technical employees can help you to arrange the layout and installation of whole process line based on your real situation;

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.