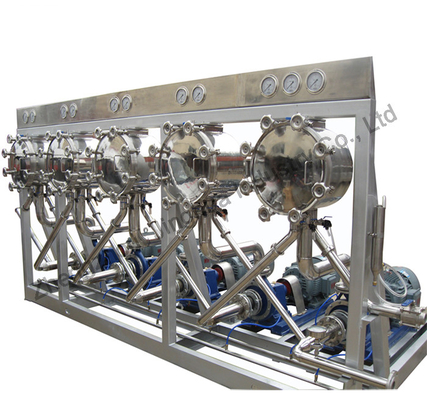

Customized Cassava Starch Processing Line Hydrocyclone Machine Stainless Steel

Product Details:

| Place of Origin: | Henan |

| Brand Name: | JingHua |

| Model Number: | Hydrocyclone |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 1640*2490*2222 mm |

| Delivery Time: | 10 work days |

| Payment Terms: | L/C, D/P, D/A, Western Union, T/T, MoneyGram |

| Supply Ability: | 10 |

|

Detail Information |

|||

| Product Name: | Hydrocyclone Machine | Application: | Food Industry Machinery |

|---|---|---|---|

| Function: | Multifunction | Processing: | Cleaning-degerminating-milling-packing |

| Feature: | Easy Operation | Final Products: | Super Fine Flour |

| Material: | Stainless Steel | Advantage: | High Effective |

| Highlight: | Customized Cassava Starch Processing Line,Cassava Starch Processing Line Hydrocyclone Machine,stainless steel Cassava Starch Processing Line |

||

Product Description

Zhengzhou Jinghua starch cyclone is used for various starch and modified starch emulsion degreasing, fine residue separation, protein

separation, washing and concentration, etc.

Continuous concentration, separation and clarification of suspensions in the food industry.

Main technical parameters

|

Model |

XL325 |

XL438 |

XL516 |

XLS426 |

|

|

Plate quantity |

1 |

1 |

1 |

2 |

Group capacity: 3-12t/h

7.5-45kw/stage

Total weight: 0.3t/stage |

|

Cylinder diameter(mm) |

362 |

438 |

516 |

426 |

|

|

Cylinder norm(mm) |

10,15 |

10,15 |

10,15 |

10,15 |

|

|

Feed Pressure(MPa) |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

|

Inlet Size(mm) |

76 |

89 |

89 |

2* 89 |

|

|

Underflow Size(mm) |

48 |

48 |

57 |

76 |

|

|

Top flow Size(mm) |

57 |

57 |

76 |

2- 57 |

Advantages of hydro cyclone

1. Fully stainless steel to be sure there is no corrosion.

2. Advanced surface treatment craft. Oil and dirty resisting.

3. Widely used for starch extraction in starch processing plants.

4. Multifunction of concentration, recovery, washing and separation for hydrocyclone group.

5. Cyclone pipes are made from material of reinforced nylon with high strength, deter abrasive resistance and excellent separation result.

6. Hydroclone designing is adopted to get better starch separation according to the features of different material.

7. Pipeline of hydrocyclone group passes computer optimization design. Compact and elegant.

8. Special sealing design, friendly operation.

pre-sale service

1. Introduce the characteristics and application of the product to the customer in detail.

2. Choose economical and practical machines for customers.

3. Provide the operating data of the relevant machines.

4. Provide customers with trial operation methods.

5. Flow chart and factory design layout.

Sales service

1. Recommend the engineering conditions required to install the machine.

2. Communicate with customers on the progress of machine manufacturing in time.

3. Project planning and design services.

After-sales service

1. Personally train equipment maintenance and operation.

2. Installation and debugging of equipment until everything is normal.

3. One year warranty and provide long-term maintenance service and spare parts.

4. Provide technical support for customers to develop new products.

5. Engineers who can service machinery overseas.

Q1: Is your company a factory or a trading company?

A: Our company is a factory in Henan Province with export license, and we have been specialized in export business for more than 20 years.

Q2. What is your main business?

A: Zhengzhou Jinghua is dedicated to starch processing machinery. Starch processing line machines, such as: tapioca starch line, tapioca flour

line, potato starch line, sweet potato line, wheat starch, sago line and garri line

Q3. Can you customize products according to our requirements?

A: Yes, we have a professional technical department and can customize products according to your requirements

Q4: Can your products be assured?

A: Our machines all have CE certificates from SGS, TUV.

Q5: If we show you our factory layout, can you help us design the whole production line?

A : Yes, our experienced engineers and technicians can help you arrange the layout and installation of the entire production line according to your

actual situation;

Q6: If we have samples of new products, can you help us analyze and design the machine?

A: Yes, our technical department can help you analyze, design and test the new products you offer.

![]()