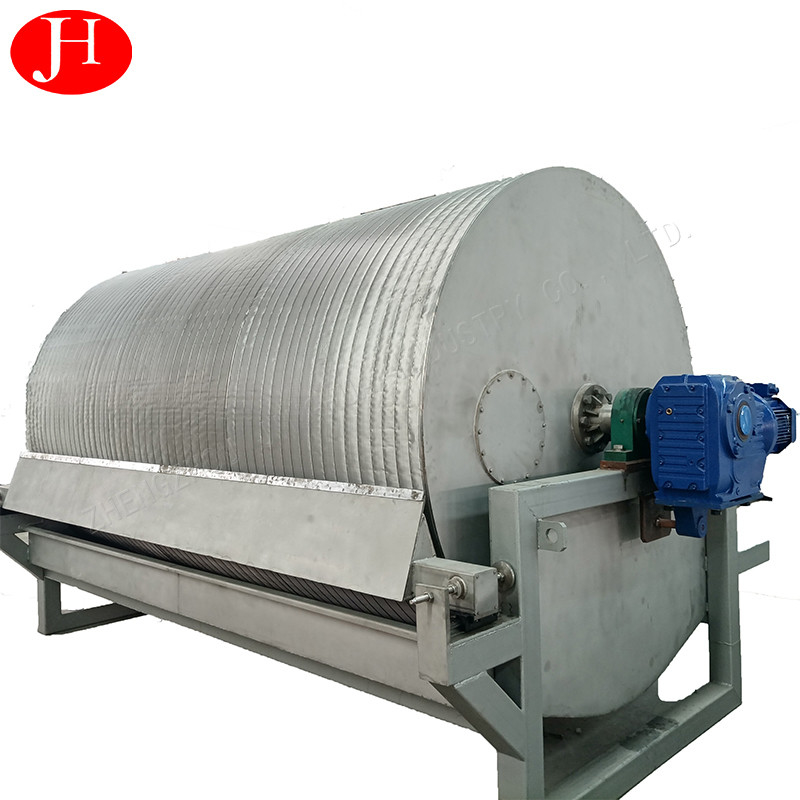

Electric Starch Vacuum Filter Machine Cassava Starch Processing Equipment

Product Details:

| Place of Origin: | Henan |

| Brand Name: | JingHua |

| Model Number: | vacuum filter |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 5060*3150*3010 mm |

| Delivery Time: | 10 work days |

| Payment Terms: | L/C, D/P, D/A, Western Union, T/T, MoneyGram |

| Supply Ability: | 10 |

|

Detail Information |

|||

| Product Name: | Vacuum Filter Machine | Application: | Food Industry Machinery |

|---|---|---|---|

| Processing: | Cleaning-degerminating-milling-packing | Type: | Food Processing Machine |

| Advantage: | High Effective | Material: | Stainless Steel |

| Function: | Multifunction | Main Product: | Flour Milling Grinding Processing Machine |

| Highlight: | Starch Vacuum Filter Machine,Electric starch Filter Production Line,Potato Starch Vacuum Filter Machine |

||

Product Description

Zhengzhou Jinghua Industrial vacuum filter set the latest technology and years of experience in one, widely used in potato starch, wheat starch,

cassava starch, sweet potato sago starch and other projects of starch milk dehydration.

Main technical parameters

|

Model |

KLG12 |

KLG20 |

KLG24 |

KLG34 |

|

Vacuum degree(Mpa) |

0.04~0.07 |

0.04~0.07 |

0.04~0.07 |

0.04~0.07 |

|

Content of solid(%) |

≥60 |

≥60 |

≥60 |

≥60 |

|

Feeding density(Be°) |

16-17 |

16-17 |

16-17 |

16-17 |

|

Capacity(t/h) |

4 |

6 |

8 |

10 |

|

Power |

3 |

4 |

4 |

4 |

|

Drum rotary speed(r/min) |

0-7.9 |

0-7.9 |

0-7.9 |

0-7.9 |

|

Weight(kg) |

3000 |

4000 |

5200 |

6000 |

|

Dimension(mm) |

3425x2312x2213 |

4775x2312x2213 |

4785x2630x2600 |

5060x3150x3010 |

Working principle

Rotary drum vacuum filter adopts vacuum suction to realize the separation of solid particles and liquid. When working, the speed regulating motor

drives the drum to rotate in the slurry tank, the vacuum pump produces a vacuum in the drum, under the action of pressure difference, the

material suspended solution forms a uniform coating on the surface of the drum, when a certain thickness is reached from the pneumatic scraper

to the starch, the filtrate enters the steam separator, so as to achieve the purpose of starch, water and gas separation.

Advantages of vacuum filter

1. Combine the latest technology with years of experience.

2. The contact part with the material is all stainless steel, compact structure and beautiful design.

3. The drum speed can be adjusted according to the actual situation on site.

4. The material is discharged through the blade. The blade is made of high rigid material and can be adjusted.

5. The running frequency of the timer is adjustable.

6. Continuous adjustment of liquid level control.

7. Low energy consumption, small footprint, stable operation.

8. Widely used for dehydration of suspension in starch processing.

Pre-sale service

1. Accept customer consultation and customize products according to customer requirements.

2. Provide customers with product processes, equipment parameters and processes, and train personnel according to customer requirements.

Sales service

1. The company sends technical personnel to the site to guide equipment installation, commissioning and training operators.

2. If there is any problem during the installation, please contact the responsible person in time. We will solve the problem in time to ensure the

installation progress.

After-sales service

1. Provide phone and video support. If the customer has any problems or equipment abnormalities in use, you can contact us by phone. We will

help customers with problems by phone or video.

2. If the phone or video does not work, the company will send technicians to the scene to solve the problem.

3. If you buy our products, we provide one-year warranty and lifetime maintenance service.

Q1: Can you provide detailed parameters and drawings of the equipment?

A: Yes, you can contact us by email, we will provide you with the detailed parameters and drawings of the equipment.

Q2:How long is the warranty period of the equipment?

A:After the successful installation and commissioning of the equipment, there is a one-year warranty period.

Q3:What kind of after-sales service do you provide?

A:Provide after-sales service for customers through telephone, video guidance, on-site maintenance, etc.

Q4: Are your products can be assured ?

A: Our machines are all have CE certificate by SGS, TUV.

Q5: If we show you our layout of factory, can you help us to design the whole process line?

A : Yes, our experienced engineers and technical employees can help you to arrange the layout and installation of whole process line based on

your real situation;

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.

![]()