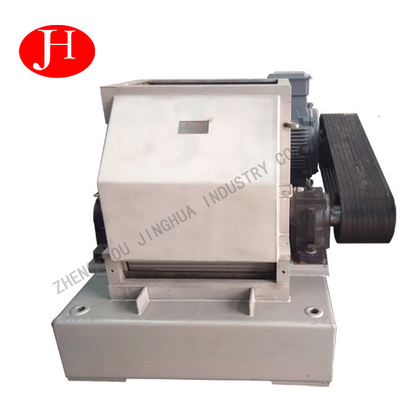

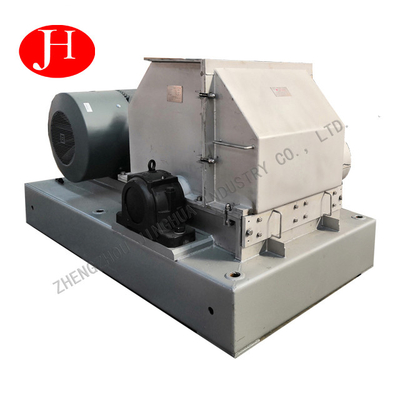

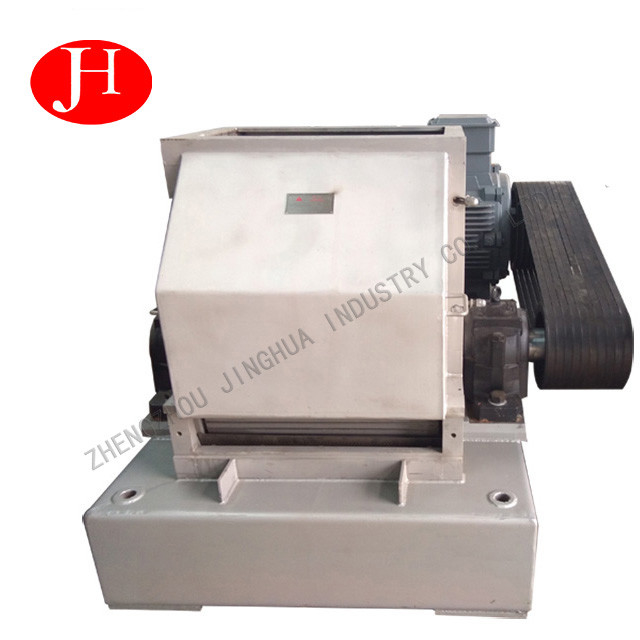

250 Kw Rasper Cassava Starch Grinder Equipment Production Line Stainless Steel

Product Details:

| Place of Origin: | Henan |

| Brand Name: | JingHua |

| Model Number: | Rasper |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 3100*800*650 mm |

| Delivery Time: | 10 work days |

| Payment Terms: | L/C, D/P, D/A, Western Union, T/T, MoneyGram |

| Supply Ability: | 10 |

|

Detail Information |

|||

| Product Name: | Rasper | Machine: | Cassava Starch Making Machine |

|---|---|---|---|

| Application: | Food Industry Machinery | Price: | Negotiable |

| Material: | Stainless Steel | Drum Diameter: | 840 Mm |

| Final Products: | Super Fine Maize Flour | Type: | Food Processing Machine |

| Highlight: | Rasper Cassava Starch Grinder Equipment,Cassava Starch Grinder Equipment,250 Kw Cassava Starch Grinder Line |

||

Product Description

Sweet potato grinding machine introduction

Sweet potato starch is mainly stored in the fleshy part of the root, the raw material particles are relatively large, the internal tissue is not easy to

destroy, the use of multiple filing, fully destroy the potato block structure, can make small starch particles can be smoothly free from the root,

improve the extraction rate of starch.

Key Technology & Innovation Potions

1. All parts in contact with raw material are made of food-grade stainless steel, which protects materials from outer pollution.

2. High rotating speed, high line speed, excellent rasping performance, uniform particle, and high starch ionization rate.

3. Rotor is calibrated with international advanced dynamic-balance instrument, meeting G1 standard.

4. Components(bearings for example) are imported from Europe with longer service life

5. Unique sieve-tension gear makes disassembly easy.

6. Saw Blade is manufactured with special steel by special process, with higher hardness and wear resistance.

7. Rasping bulk is cast of high-chromium iron, hardness reaching HRC60, having excellent wear resistance.

8. Unique drum groove and layering instrument design benefits saw blade changing.

Main technical parameters

|

Model |

DCM8435 |

DCM8450 |

DCM8465 |

DCM1070 |

|

Main shaft rotating speed(r/min) |

2100 |

2100 |

2100 |

1470 |

|

Drum diameter(mm) |

Φ840 |

Φ840 |

Φ840 |

Φ1100 |

|

Drum width(mm) |

350 |

500 |

650 |

700 |

|

Power(Kw) |

110 |

160 |

200 |

250 |

|

Capacity(t/h) |

20-23 |

30-33 |

35-40 |

40-45 |

|

Dimension(mm) |

2170x1260x1220 |

2170x1385x1250 |

2170x1650x1380 |

3000x1590x1500 |

The working principle of rasper

The material enters into the body of the file mill shell through the upper entrance, and is broken by the impact, shear and grinding effect of the

saw blade moving at high speed. The lower part of the rotor is equipped with a screen screen. The material smaller than the size of the screen

hole is discharged through the screen plate, and the particles larger than the size of the screen hole are blocked and remain on the screen plate

to continue to be hit and grinder by the saw blade.

our service

pre-sale service

1. Introduce the detailed features and applications of the product to customers.

2. Choose economical and practical machines for customers.

3. Provide the operating data of related machines.

4. Provide audition means for customers.

5. Flow chart and factory design layout.

Sales service

1. Recommend the engineering conditions required for machine installation.

2. Communicate with customers on the manufacturing progress of the machine in time.

3. Project planning and design services.

After-sales service

1. Equipment maintenance and personal operation training.

2. Equipment installation and debugging until everything is normal.

3. One year warranty and provide long-term maintenance service and spare parts.

4. Provide technical support for customers to develop new products.

5. Engineers who can repair machinery overseas.

FAQ

Q1: Is your company a factory or a trading company?

A: Our company is a factory in Henan Province with an export license, and we have been specialized in export business for more than 20 years.

Q2. What is your main business?

A: Zhengzhou Jinghua is dedicated to starch processing machinery. Starch production line equipment, such as: tapioca starch production line,

tapioca flour production line, potato starch production line, sweet potato production line, wheat starch, sago production line, Gary production line

Q3: Where is your factory located? How can I visit there?

A: Our address: the intersection of Zhengyun Road and Guanggu Road, Guangwu Town, Zhengzhou City, Henan Province, China.

Warmly welcome you to visit us!

Q4: Can your products be assured?

A: Our machines all pass ISO9001:2001 and have CE certificates from SGS, TUV.

Q5: If we show you our factory layout, can you help us design the whole production line?

A: Yes, our experienced engineers and technicians can help you arrange the layout and installation of the whole process line according to your actual situation;

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.

![]()