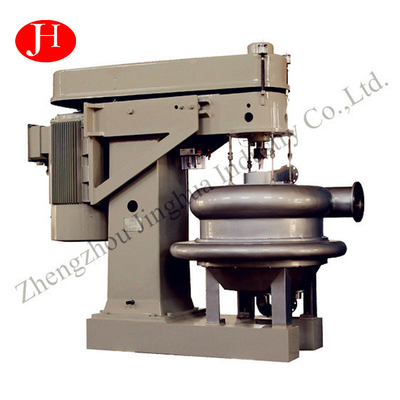

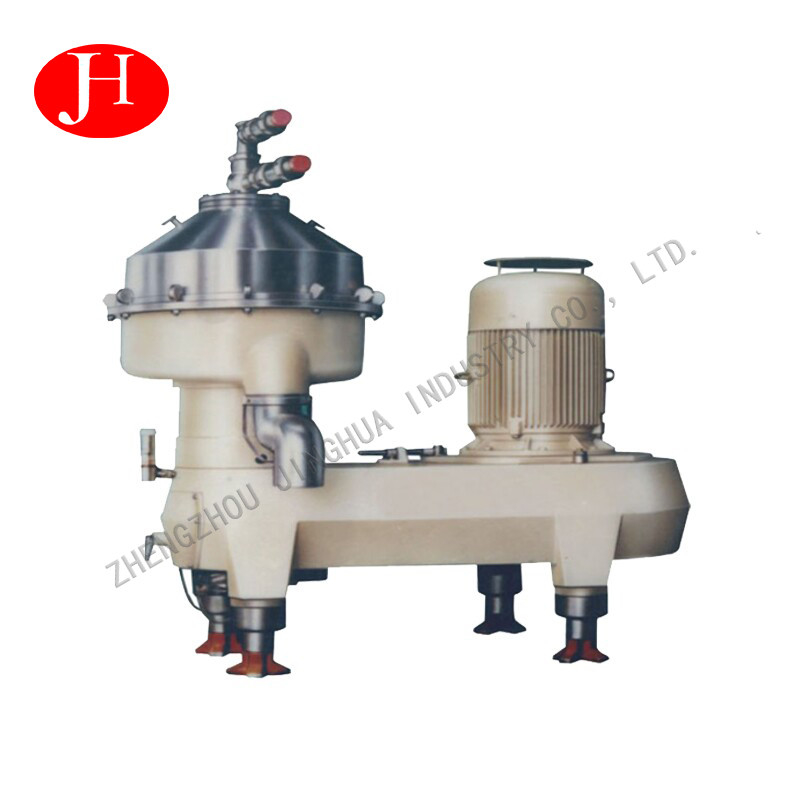

Potato Flour Disc Separator Machine Cassava Starch Processing Equipment

Product Details:

| Place of Origin: | Henan |

| Brand Name: | JingHua |

| Model Number: | Disc Separator Machine |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 3950*2050*3050 mm |

| Delivery Time: | 10 work days |

| Payment Terms: | L/C, D/P, D/A, Western Union, T/T, MoneyGram |

| Supply Ability: | 10 |

|

Detail Information |

|||

| Product Name: | Fiber Separator Machine | Application: | Food Industry Machinery |

|---|---|---|---|

| Final Products: | Super Fine Flour | Type: | Food Processing Machine |

| Processing Type: | Cleaning-milling-packing | Advantage: | High Effective |

| Feature: | Easy Operation | Processing: | Full-automatic Milling Machine |

| Highlight: | Potato Starch Flour Disc Separator Machine,Cassava Starch Processing Separator Equipment,Food Industry Cassava Starch Separator Equipment |

||

Product Description

Description of Disc separator

The disc separator is a separator with continuous discharge from the nozzle. Due to its high separation factor, it has a good separation effect for

the separation of suspensions with less solid content and various emulsions.

The machine can also be used in pharmaceutical, chemical, food and other industries to produce raw materials suitable for the function of the

machine.

Technical parameters

|

Model |

GK800/GKH800 |

GK1250/GKH1250 |

GK1600/GKH1600 |

|

Bowl diameter(mm) |

800/800 |

1250/1250 |

1600/1600 |

|

Bowl lenght(mm) |

400/450 |

600/600 |

800/1000 |

|

Bowl’s rotating speed(r/min) |

1400/1550 |

1200/1200 |

900/950 |

|

Separating factor |

876/1070 |

1006/1006 |

725/808 |

|

Dimension (mm) |

2480x1650x1300 2030x1960x1350 |

3100 x 2070 x 1775 2870 x 2470 x 1955 |

3885 x 2726 x 2220 4050 x 2745 x 2295 |

|

Weight(Kg) |

3200/5500 |

8800/11150 |

11550/16550 |

|

Power(kw) |

30/45 |

55/90 |

90/132 |

Pre-sale service

1. Introduce the features and applications of the products to customers in detail.

2. Choose economical and practical machines for customers.

3. Provide relevant machine operation data.

4. Provide customers with the means of trial operation.

5. Flow chart and factory design plan.

After-sales service

1. Equipment maintenance and operation training.

2. Installation and commissioning of equipment until everything is normal.

3. One year warranty, and provide long-term maintenance services and spare parts.

4. Provide technical support for customers to develop new products.

5. Engineers can be sent overseas to repair machinery.

6. Provide installation/operation/service/maintenance manuals in English.

Q1: Can you provide the detailed parameters and drawings of the equipment?

A: Yes, you can contact us by E-mail and we will provide you with the detailed parameters and drawings of the equipment.

Q2: How long is the warranty period of the equipment?

A: One year warranty after successful installation and commissioning of the equipment.

What kind of after-sales service do you offer?

A: Provide after-sales service to customers through telephone, video guidance, on-site maintenance and other ways.

Can you trust your products?

A: Our machines are CE certified by SGS and TUV.

If we show you the layout of the factory, can you help us design the entire production line?

A: Yes, our experienced engineers and technicians can help you arrange the layout and installation of the entire process line according to your

actual situation;

If we have a sample of the new product, can you help us analyze and design the machine?

A: Yes, our technical department can help you analyze, design and test your new products.

![]()