High Efficiency Cassava Flour Making Crusher Machine Processing Line

Product Details:

| Place of Origin: | Henan |

| Brand Name: | JingHua |

| Model Number: | Crusher |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 3000*1490*1500 mm |

| Delivery Time: | 10 work days |

| Payment Terms: | L/C, D/P, D/A, Western Union, T/T, MoneyGram |

| Supply Ability: | 10 |

|

Detail Information |

|||

| Product Name: | Crusher Machine | Application: | Food Flour Grinding Mill Machine |

|---|---|---|---|

| Processing Type: | Cleaning-milling-packing | Feature: | High Efficiency |

| Final Products: | Flour Milling Processing Machinery | Advantage: | Large Capacity |

| Type: | Food Processing Machine | Processing: | Cleaning-degerminating-milling-packing |

| Highlight: | Cassava Flour Crusher Processing Line,High Efficiency Cassava Flour Making Crusher,large capacity Cassava Flour crusher machine |

||

Product Description

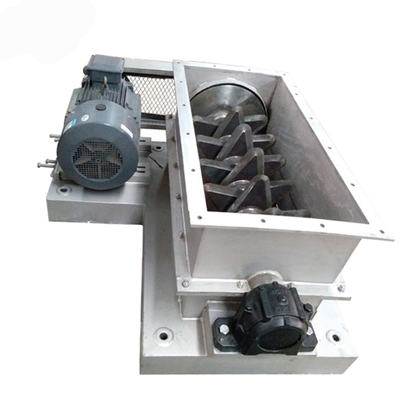

Zhengzhou Jinghua Industry crusher is newly designed with compact structure, easy disassembly and low maintenance cost. The machine is

widely used for cracking big materials. The raw material is usually fresh cassava tube, fresh sweet potato and after crushing you can get the

finished product with a 20-30mm size. It is a precrushing.

Main technical parameters

|

Model |

Blade Number (piece) |

Rotor length (mm) |

Power (Kw) |

Dimension (mm) |

Weight (kg) |

Capacity (t/h) |

|

|

DPS5050 |

9 |

550 |

7.5/11 |

1030x1250x665 |

650 |

10-15 |

Diameter of rotor:Φ480mm Speed of rotor:1200r/min |

|

DPS5076 |

11 |

760 |

11/15 |

1250x1300x600 |

750 |

15-30 |

|

|

DPS50100 |

15 |

1000 |

18.5/22 |

1530x1250x665 |

900 |

30-50 |

|

|

DPS60100 |

15 |

1000 |

30/37 |

1530x1400x765 |

1100 |

60-80 |

Advantages of crusher

1. Independent research and development, combined with similar equipment performance at home and abroad, combined with their own years of

experience.

2. New design, compact structure, easy disassembly, low maintenance cost.

3. Small size, large capacity, medium speed, low energy consumption, stable operation.

4. Avoid repeated cutting materials and improve cutting ability. The blades are specially made to last. 5. The parts in contact with the material are

made of stainless steel to ensure that the material is not contaminated. 6. The machine is widely used in the crushing of large materials.

There are four steps to making starch

1. Cleaning: remove stone sand and impurities in raw materials.

2. Crushing: Destroy the fiber structure and free the starch granules.

3. Separator: desanding, desilting, degreasing, micro-slag separation, protein separation, washing and concentration of various starches and

modified starch emulsions for starch slurry.

4. Drying and packing: dehydrate the wet starch, sieve and pack.

Our Services

Pre-sale service

1. Introduce the features and applications of the products to customers in detail.

2. Choose economical and practical machines for customers.

3. Provide relevant machine operation data.

4. Provide customers with the means of trial operation.

5. Flow chart and factory design plan.

Sales service

1. Recommend the engineering conditions required for installing the machine.

2. Timely communicate with customers about the manufacturing progress of the machine.

3. Project planning and design services.

After-sales service

1. Equipment maintenance and operation training.

2. Installation and commissioning of equipment until everything is normal.

3. One year warranty, and provide long-term maintenance services and spare parts.

4. Provide technical support for customers to develop new products.

5. Engineers can be sent overseas to repair machinery.

Are you a factory or a trading company?

A: Our company is a factory in Henan Province with an export license. We have been engaged in the export business for more than 20 years.

Q2. What is your main business?

A: Zhengzhou Jinghua is a company specializing in the production of starch processing machines. Starch processing line, such as: cassava

starch production line, cassava flour production line, potato starch production line, sweet potato production line, wheat starch production line,

sago production line, garri production line

The third season. Can you make customized products according to our requirements?

A: Yes, we have a professional technical department that can customize products according to your requirements

Can you trust your products?

A: Our machines are CE certified by SGS and TUV.

If we show you the layout of the factory, can you help us design the entire production line?

A: Yes, our experienced engineers and technicians can help you arrange the layout and installation of the entire process line according to your

actual situation;

If we have a sample of the new product, can you help us analyze and design the machine?

A: Yes, our technical department can help you analyze, design and test your new products.

![]()