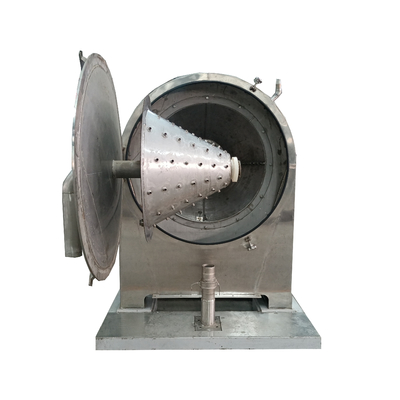

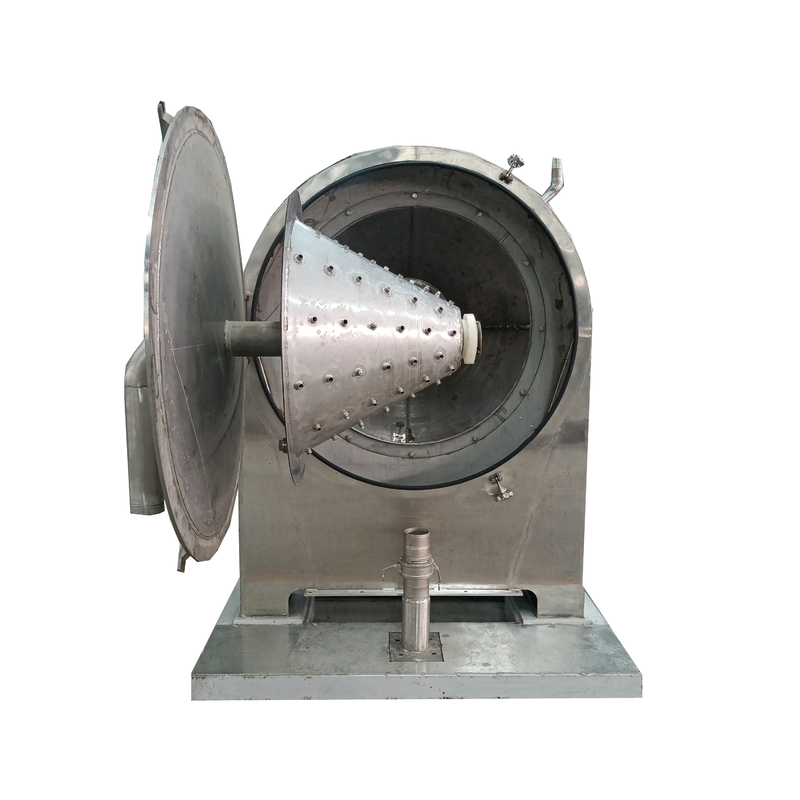

Cassava Starch Slurry Fiber Separator Plant Centrifuge Sieve Equipment

Product Details:

| Place of Origin: | Henan |

| Brand Name: | JingHua |

| Model Number: | Centrifuge Sieve |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | 3000*1590*1500 mm |

| Delivery Time: | 10 work days |

| Payment Terms: | Western Union, T/T, D/P, D/A, L/C |

| Supply Ability: | 10 |

|

Detail Information |

|||

| Product Name: | Centrifuge Sieve | Application: | Food Industry Machinery |

|---|---|---|---|

| Final Products: | Super Fine Flour | Processing Type: | Cleaning-milling-packing |

| Processing: | Easy Operation | Main Product: | Flour Milling Processing Machinery |

| Highlight: | centrifuge sieve cassava flour processing machine,food industry cassava flour processing machine,centrifuge sieve cassava starch processing machine |

||

Product Description

Main technical parameters

|

Model |

Basket diameter (mm) |

Main shaft speed (r/min) |

Working model |

Power (Kw) |

Dimension (mm) |

Weight (t) |

|

DLS85 |

850 |

1050 |

continuous |

18.5/22/30 |

1200x2111x1763 |

1.5 |

|

DLS100 |

1000 |

1050 |

continuous |

22/30/37 |

1440x2260x1983 |

1.8 |

|

DLS120 |

1200 |

960 |

continuous |

30/37/45 |

1640x2490x2222 |

2.2 |

Advantages of centrifuge sieve

1. Combining the latest technology and years’ experience into a whole.

2. Key components introduced abroad, lone service life, low maintenance cost.

3. All parts contact with material are stainless steel, no material contamination.

4. Sieve basket is calibrated through dynamic equilibrium by domestic authority body.

5. Sieve made from laser perforating on titanium alloy plate.

6. To facilitate the automatic design for centrifugal sieve group, CIP system and chain automatic control can be easily realized.

7. Advanced surface treatment technology ensuring the good appearance and resistance of oil and dirt.

8. Nozzles tested by strict examination in pressure and flow rate.

9. Big capacity, low power consumption, stable operation, high starch extraction rate and easy installation.

10. Widely used for starch extraction in starch processing factory.

pre-sale service

1. Accept customer consultation and customize products according to customer requirements.

2. Provide customers with product technology, equipment parameters and process flows, and train personnel according to customer

requirements.

Sales service

1. The company sends technical personnel to the site to guide equipment installation, debugging and train operators.

2. If you have any questions during the installation process, please contact the person in charge in time. We will solve the problem in time and ensure the installation progress.

After-sales service

1. Provide phone and video support. If customers have any problems or equipment abnormalities during use, they can contact us by phone. We will help customers solve their problems by phone or video.

2. If the phone or video cannot be connected, the company will send technicians to the site to repair the problem.

3. For products purchased from our company, we provide one-year warranty and lifetime maintenance services.

Q1: Is your company a factory or trading company?

A1: Our company is a factory in Henan Province ,with export license and we have done export business over 20 years professionally.

Q2.What is your main business?

A2: Zhengzhou jinghua is devoted to starch processing machine. The machine of starch processing line , such as : cassava starch line , cassava flour line , potato starch line , sweet potato line , wheat starch ,sago line and garri line.

Q3:Where is your factory located? How can I visit there?

A3: Our add: Zhengyun Road and Guanggu Road intersection , Guangwu Town , Zhengzhou City , Henan Province , China.

Warmly welcome to visit us!

Q4: Are your products can be assured ?

A4: Our machines are all passed ISO9001:2001 and have CE certificate by SGS, TUV.

Q5: If we show you our layout of factory, can you help us to design the whole process line?

A5: Yes, our experienced engineers and technical employees can help you to arrange the layout and installation of whole process line based on your real situation.

Q6: If we have samples of new products, can you help us to analysis and design the machine?

A: Yes, Our technical department can help you to analysis, design and test the new products you offered.

![]()