Large Capacity Potato Starch Fiber Separator Machine

Product Details:

| Place of Origin: | Zhengzhou City,China |

| Brand Name: | JINGHUA |

| Certification: | CE |

| Model Number: | GDSF2*10*100 GDSF2*10*83 GDSF1*10*83 GDSF1*10*100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Customize the wooden case according to the size of the product,Each container can hold 4-6 pieces of products |

| Delivery Time: | 5-14 work days after receiving pre payment |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 10 sets/month |

|

Detail Information |

|||

| Product Name: | High Efficiency Potato Starch Sifter | Application: | Potato Starch Fiber Separator Machine |

|---|---|---|---|

| Useful Life: | 20 Years | Energy: | Electric |

| Service: | Overseas Installation | Condition: | New |

| Warranty: | 12 Months | Customized: | Customized |

| Highlight: | sifter Fiber Separator Machine,starch vibration sifter |

||

Product Description

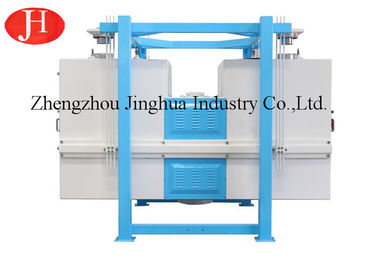

Vibration Starch Sifter Potato Starch Fiber Separator Making Machine

Introduction of starch sifter

Zhengzhou jinghua starch sifter is widely used in starch industry and it is proved the best sifter in starch sifting. The sieve body is composed of many layer sieve lattices and the sieve cases are made of excellent bass wood. Each layer connects closely as the form of step in the rim to ensure good sealing performance and convenient maintenance. Suspender is made from glass fiber reinforced plastic with durable life.

It is widely used for sieving dry starch before starch packing in corn starch, cassava starch, potato starch and sweet potato starch and wheat starch sago starch processing project.

Features of starch sifter

1. Long sieving road.

2. Small occupying space.

3. High efficiency and large capacity.

4. Energy saving and stable operation.

5. Easy maintenance.

6. Shifter screen is varied 40-120 mesh according to different material.

7. Shifter screen material is stainless steel.

8. Shifter frame can be made of carbon steel or stainless steel.

Main technical parameters

| Model |

Bin (Piece) |

Number of sieves (piece) |

Capacity (t/h) |

Diameter (mm) |

Power (Kw) |

Weight (kg) |

Dimension (mm) |

| GDSF2x10x100 | 2 | 10-12 | 8-10 | Φ45-55 | 2.2 | 1200-1500 | 2530x1717x2270 |

| GDSF2x10x83 | 2 | 8-12 | 5-7 | Φ45-55 | 1.5 | 730-815 | 2120x1440x2120 |

| GDSF1x10x83 | 4.5 | 2-3 | 3-4 | Φ40 | 0.75 | 600 | 1380x1280x1910 |

| GDSF1x10x100 | 6.4 | 3-4 | 4-5 | Φ40 | 1.5 | 750 | 1620x1620x1995 |

| GDSF1x10x120 | 7.6 | 4-5 | 5-6 | Φ40 | 1.5 | 950 | 1890x1890x2400 |

Packing & Shipping

Packing : Customize the wooden case according to the size of the product.

Delivery: 14 days after receiving pre-payment (on time according to contract strictly).

![]()

Company Information

Jinghua company is an engineering and technical company specializing in starch engineering design, equipment manufacturing, engineering installation and debugging, technical personnel training and other work. Has two modern large factory, engineering and technical personnel more than 30 people, can provide installation services overseas .Company for China starch industry association executive director units, executive director of the association of Chinese cassava starch industry unit.

Mr. Wang yanbo, chairman of the board, has published 7 scientific works, 6 national standards and 30 academic papers, across a country: "ten five" to "thirteen, five" national key r&d projects and provincial major research project over 10, with more than 10 national patents, won awards at all levels more than 20. Has participated in more than 80 domestic and foreign starch engineering design work, its advanced processing technology and technology has reached the world's leading level.

Our Factory

![]()

Our Office

![]()

Our Workshop

![]()

Our Workers

![]()