30Kw Slurry Fiber Centrifuge Sieve Potato Starch Machine

Product Details:

| Place of Origin: | Zhengzhou City,China |

| Brand Name: | JINGHUA |

| Certification: | CE |

| Model Number: | DLS85 DLS100 DLS120 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Customize the wooden case according to the size of the product,Each container can hold 4-6 pieces of products |

| Delivery Time: | 5-14 work days after receiving pre payment |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 10 sets/month |

|

Detail Information |

|||

| Product Name: | Centrifuge Sieve | Advantage: | Good Effect |

|---|---|---|---|

| Dimension: | 1200*2111*1763mm | Useful Life: | 20 Years |

| Capacity: | 5-20 T/h | Service: | Overseas Installation |

| Warranty: | 1 Years | Energy: | Electric |

| Power: | 30 Kw | Working Model: | Continuous |

| Highlight: | Starch Slurry Fiber Separator,Centrifuge Sieve Potato Starch Machine,30Kw Slurry Fiber Separator |

||

Product Description

30 Kw Centrifuge Sieve Potato Starch Machine Starch Slurry Fiber Separator Washing Plant

Description of potato starch making machine

Centrifugal Sieve is used to separate the fine fiber from the starch slurry, which is widely used in the processing of potato, cassava, sweet potato, wheat, rice, sago and other grain starch extraction.

Main technical parameters

|

Model

|

Basket diameter(mm) | Main shaft speed(r/min) | Working model |

Power (Kw) |

Dimension (mm) |

Weight (t) |

| DLS85 | 850 | 1050 | continuous | 18.5/22/30 | 1200x2111x1763 | 1.5 |

| DLS100 | 1000 | 1050 | continuous | 22/30/37 | 1440x2260x1983 | 1.8 |

| DLS120 | 1200 | 960 | continuous | 30/37/45 | 1640x2490x2222 | 2.2 |

Advantages of centrifuge sieve

1. Combining the latest technology and years’ experience into a whole.

2. Key components introduced abroad, lone service life, low maintenance cost.

3. All parts contact with material are stainless steel, no material contamination.

4. Sieve basket is calibrated through dynamic equilibrium by domestic authority body.

5. Sieve made from laser perforating on titanium alloy plate.

6. To facilitate the automatic design for centrifugal sieve group, CIP system and chain automatic control can be easily realized.

7. Advanced surface treatment technology ensuring the good appearance and resistance of oil and dirt.

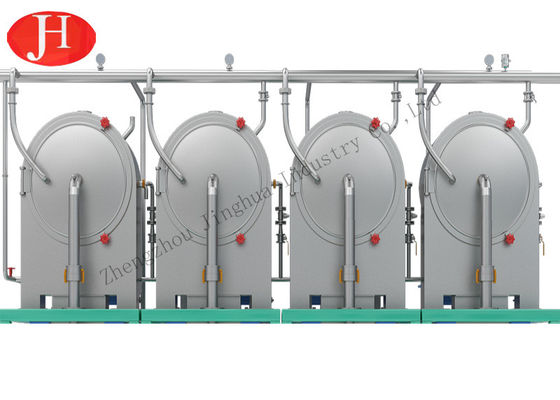

Real application case

![]()

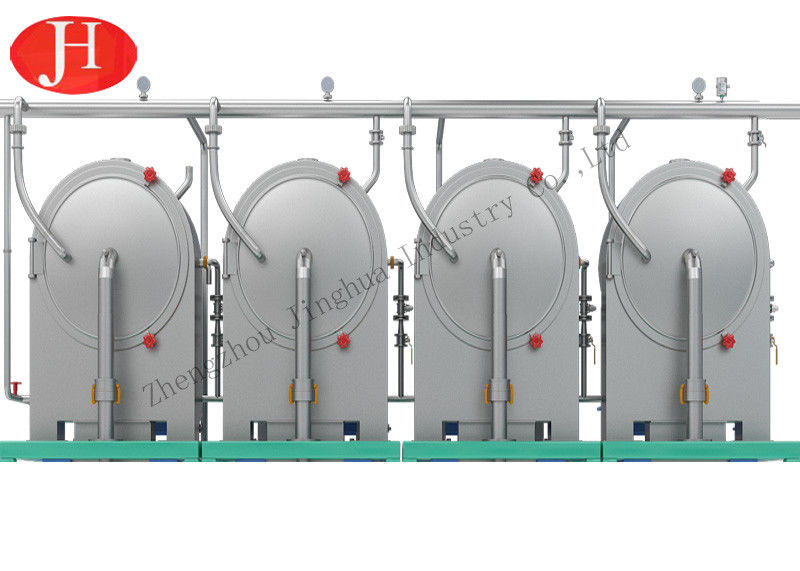

Packing & Shipping

Packing & Shipping: Customize the wooden case according to the size of the product.

Delivery: 14 days after receiving pre-payment (on time according to contract strictly).

![]()

Our Service

Pre-sale service

1.Introducing detail features and application of the products to customer.

2.Selecting economical and practical machines for customer.

3.Providing operation data of the related machine.

4.Providing means of trial performance for customer.

5.Flow chart and factory designing layout .

Sale service

1.Recommending engineering conditions required for installation of the machine.

2.Communicating the manufacturing progress of machines with customer in time.

3.Project planning and design services.

After-sale service

1.Training of equipment maintenance and operating personally.

2.Installation and commissioning of equipment until everything is functional.

3.One year warranty and providing long-term maintenance service and spare parts.

4.Giving technical support to customer for developing new product.

5.Engineers available to serve machinery overseas.