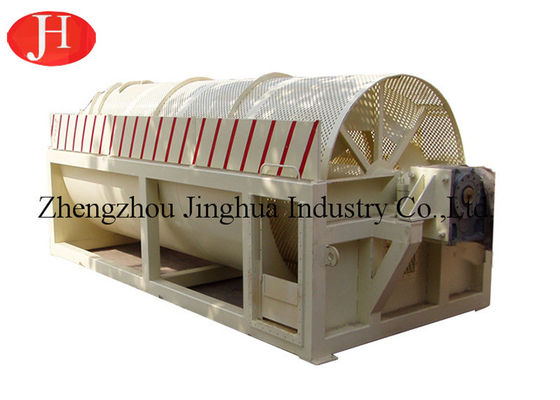

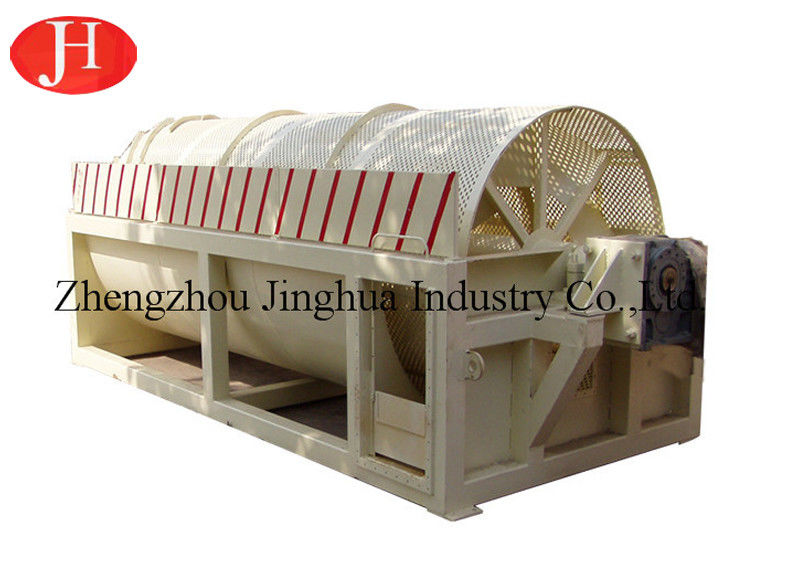

50t SS304 Rotary Washer Potato Starch Making Machine

Product Details:

| Place of Origin: | Zhengzhou City,China |

| Brand Name: | JINGHUA |

| Certification: | CE |

| Model Number: | DQXJ190x450 DQXJ190x490 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Customize the wooden case according to the size of the product,Each container can hold 4-6 pieces of products |

| Delivery Time: | 5-14 work days after receiving pre payment |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 5 sets/month |

|

Detail Information |

|||

| Product Name: | Rotary Washer | Machine: | Potato Washing Machine |

|---|---|---|---|

| Advantages: | Large Capacity | Power: | 30 Kw |

| Weight: | 6000 Kg | Material: | Stainless Steel |

| Service: | Overseas Installation | Capacity: | 20-50 T. |

| Highlight: | Rotary Washer Potato Starch Making Machine,50t Potato Washing Machine,SS304 Potato Washing Machine |

||

Product Description

Fresh Potato Washing Machine Rotary Washer Potato Starch Production Line Supplier

Description of potato washing machine

Rotary drum washer is applied to wash potatoes, cassavas, sweet potatoes and etc. Rotary washer is the washing section machine in starch processing line and it adopts the principle of counter current to clean out mud, sand and small stones effectively.

Advantages of rotary cleaning machine

1. Combining the latest technology and years' experience into a whole

2. Adopting method of countercurrent washing, excellent washing result, mud and sand removing.

3. Reasonable feeding structure. The damage rate of raw material is under 1% and this can ensure high starch extraction yield.

4. Compact design, big capacity, energy and water saving

5. Stable operation and rational motor equipped.

Main technical parameters

|

Model

|

Drum diameter (mm) |

Drum length (mm) |

Capacity (t/h) |

Power (Kw) |

Dimension (mm) |

Weight (Kg) |

| DQXJ190x450 | Φ1905 | 4520 | 20-25 | 18.5 | 5400x2290x2170 | 5200 |

| DQXJ190x490 | Φ1905 | 4920 | 30-35 | 22 | 5930x2290x2170 | 5730 |

| DQXJ190x490 | Φ1905 | 4955 | 35-50 | 30 | 6110x2340x2170 | 6000 |

There are four steps to making potato starch

1.Cleaning:To remove the stone sand and from the raw material.

2.Crushing :To destroys the fiber structure and makes the starch particles free.

3.Separator:To removing sand ,mud from starch slurry, degreasing, microslag separation, protein separation, washing and concentration of all kinds of starch and modified starch emulsion.

4.Drying and Packing:To dehydrator the wet starch, sifter and packaged.

![]()

Our Service

Pre-sale service

1.Accept customer consultation and customize products according to customer requirements.

2.Provide customers with product process, equipment parameters and processes, and train personnel according to customer requirements.

Sale service

1.The company sent technical personnel to the scene of the on-the -spot guidance equipment installation,debugging and training operators.

2.If there is any problem during the installation, please contact the responsible person in time. We will solve the problem in time to ensure the installation progress.

After-sale service

1.Provide telephone and video support. If the customer has any problems or abnormal devices in use, you can contact us by phone. We will help the customer solve the problems by phone or video.

2.If the phone or video doesn't work, the company will send technicians to the scene to fix the problem.

3.Products purchased in our company, we provide one-year warranty and lifelong maintenance service.

Why Choose Us

Zhengzhou Jinghua company is an engineering and technical company specializing in starch engineering design, equipment manufacturing, engineering installation and debugging, technical personnel training and other work. Has two modern large factory,Can ensure the processing and delivery cycle,engineering and technical personnel more than 30 people, can provide installation services overseas and custom product for you.Our company has undertaken national and provincial scientific research projects.,with more than 30 invention patents, various honor certificate more than 20.Can provide high quality products for you.

Our Factory

![]()

Our Workshop

![]()